October & November: "specialise in making the impossible merely late."

We’re conscious that it’s been a few weeks since our last remote update blog, so we thought we should release a video of where we’re at with the latest prototype.

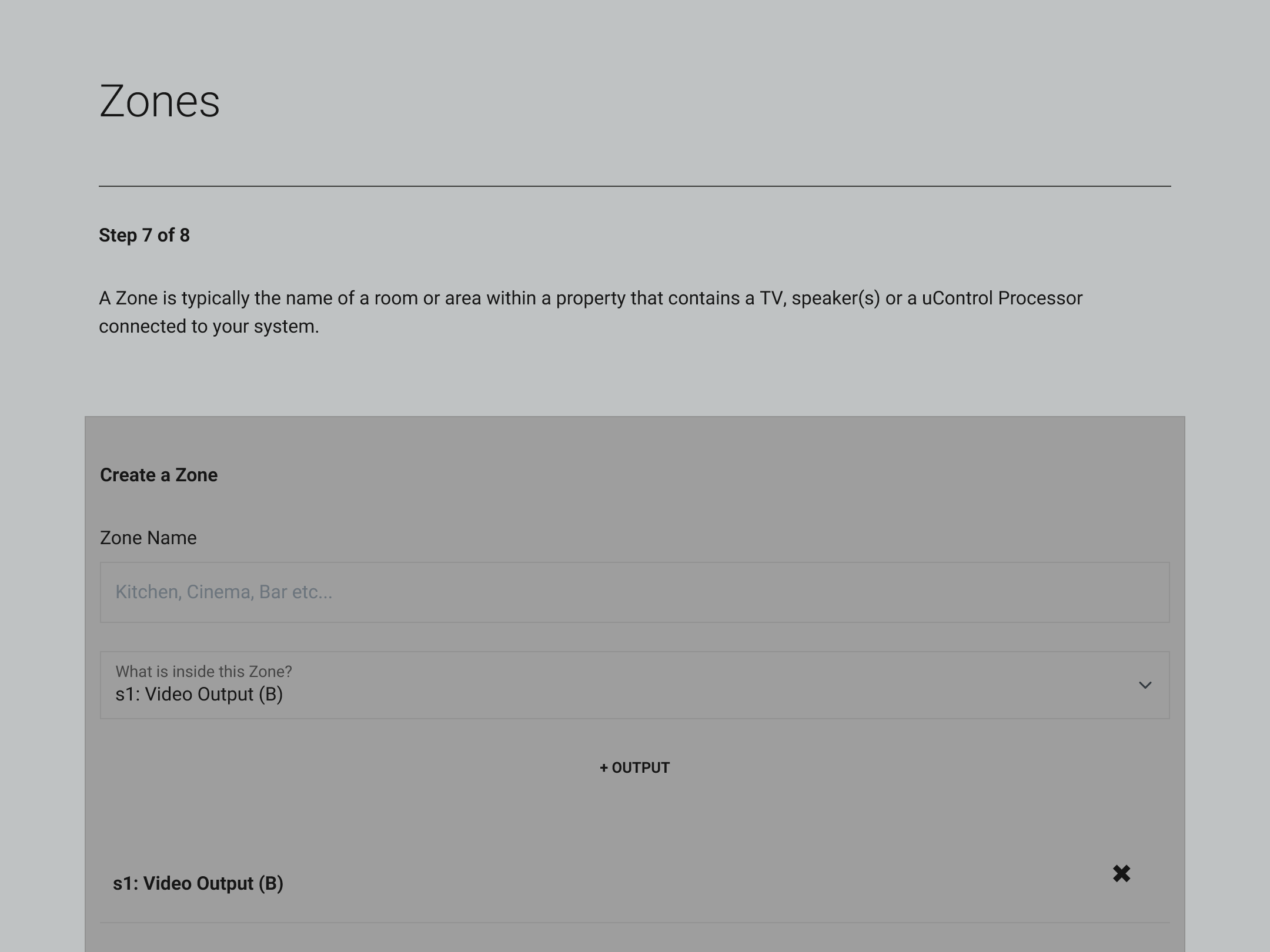

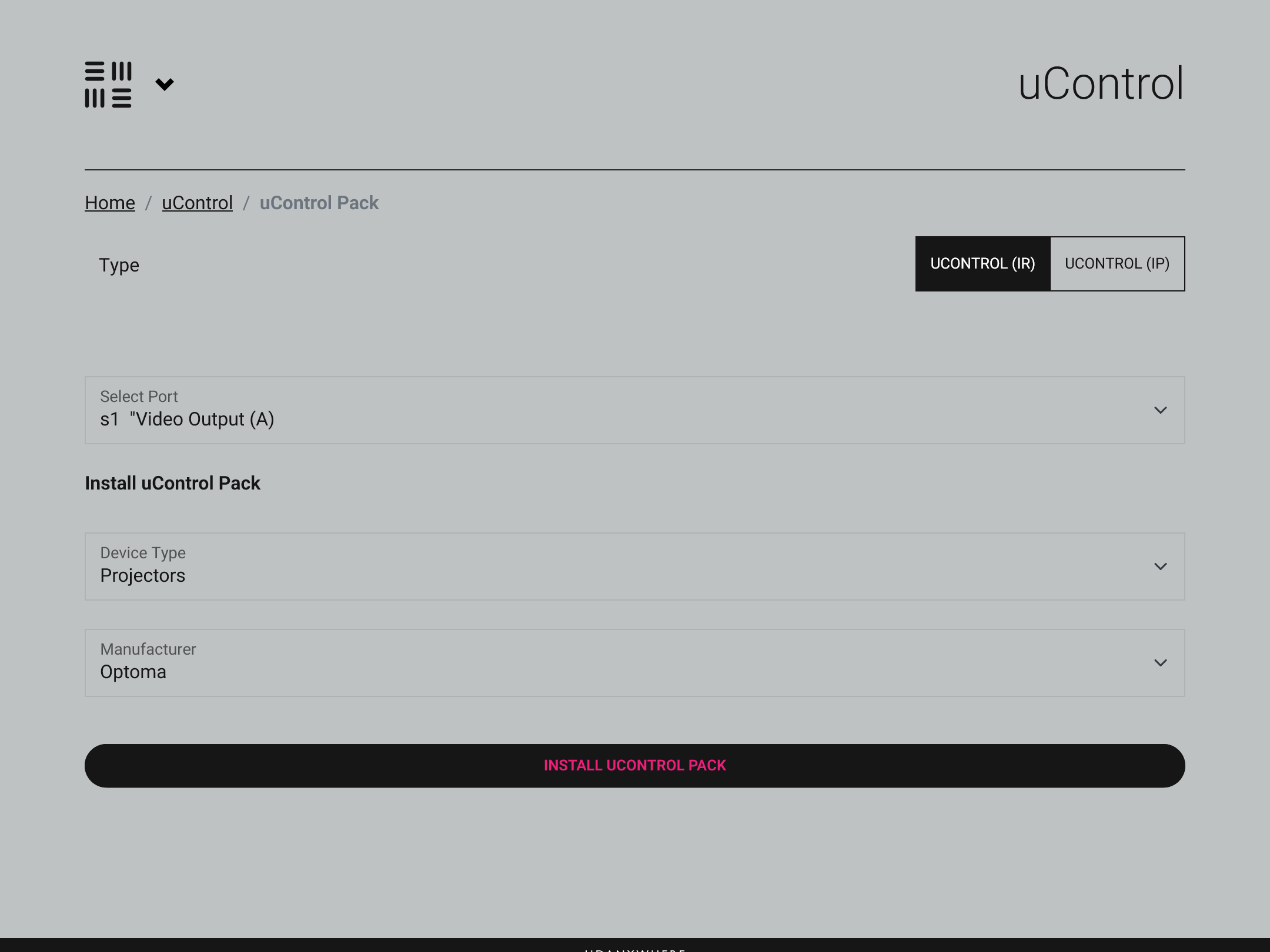

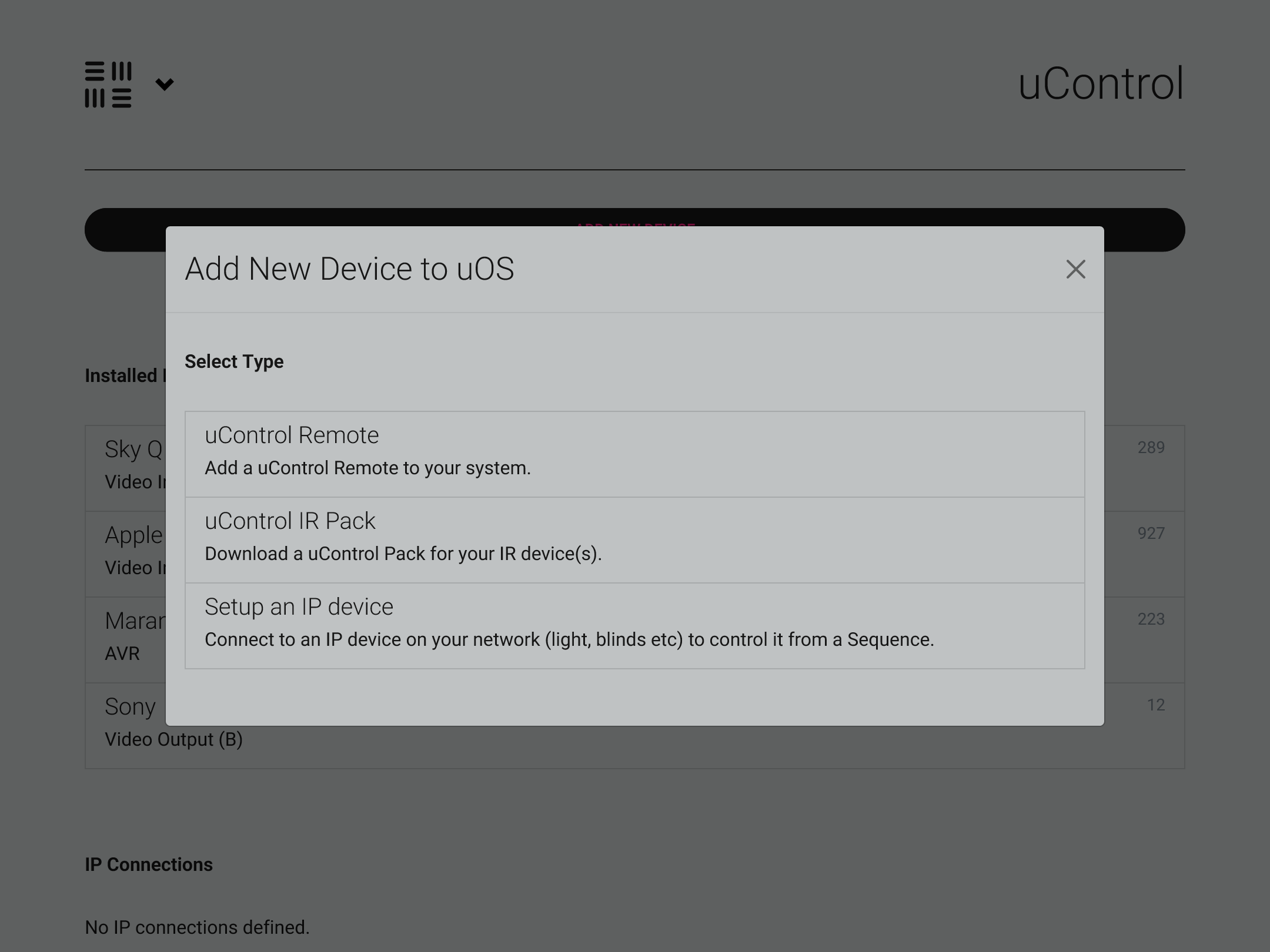

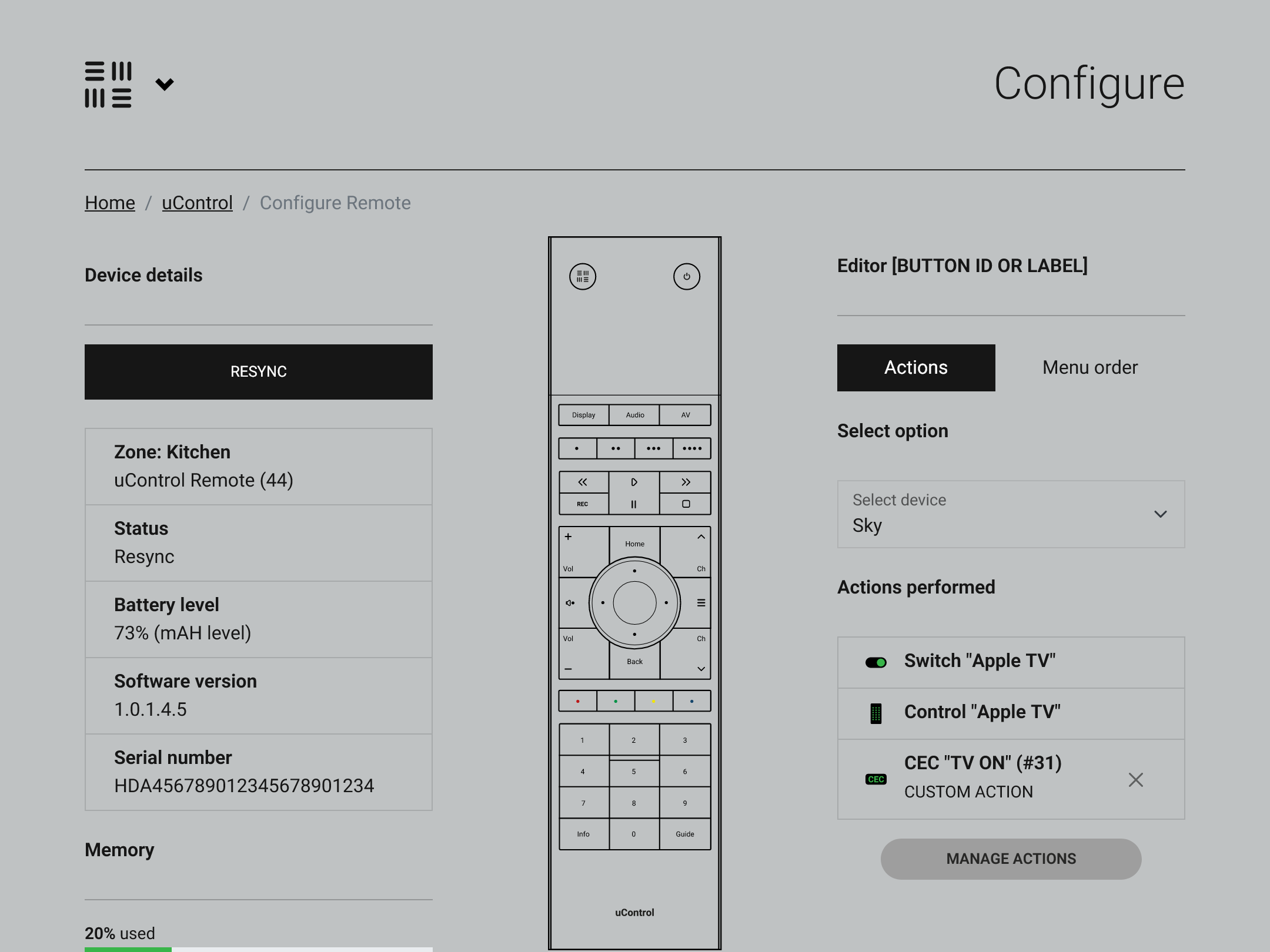

In the video Justin has taken a factory fresh uControl Remote and programmed it directly from the Zone Processor tasked with controlling the MHUB S in our office.

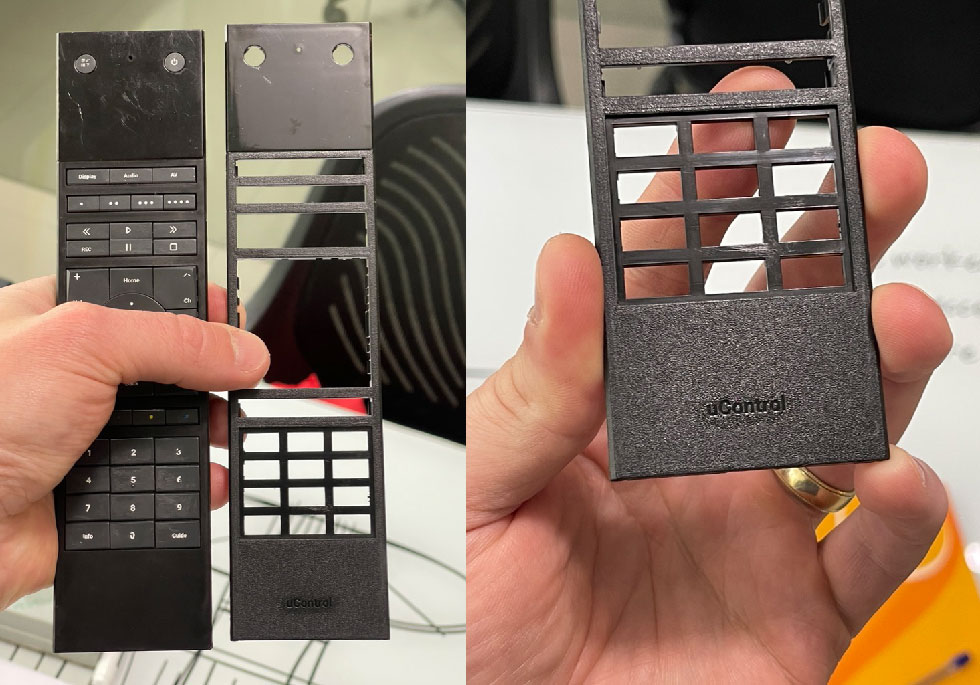

Will there ever be an end to prototyping the remote?

Yes, but sometimes you've just got to admit when things haven't gone as well as you planned! And that's how to sum up October and November - weeks of toil punctuated with a few more costly lessons regarding the fit and finish of the remote's plastic parts.

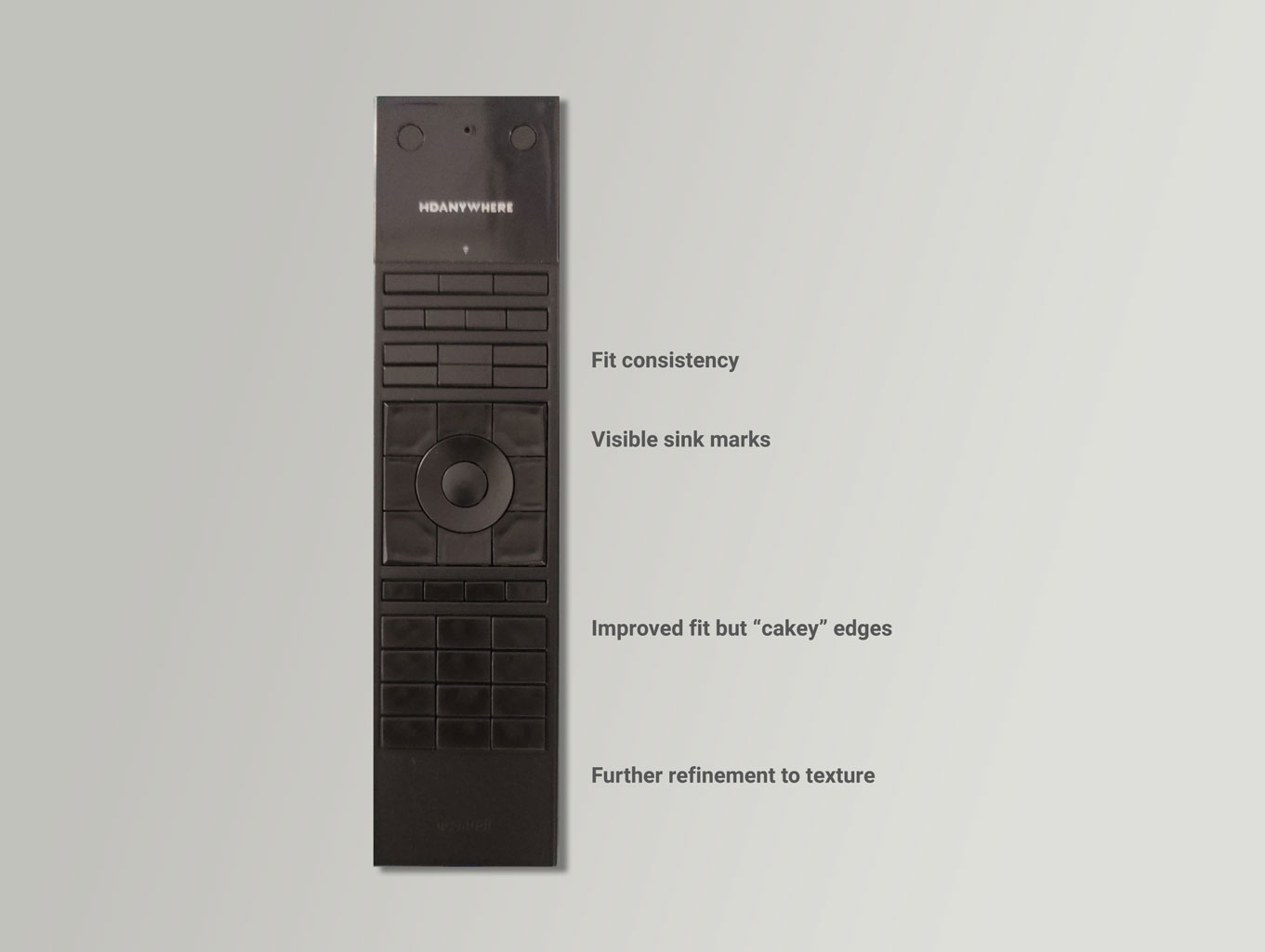

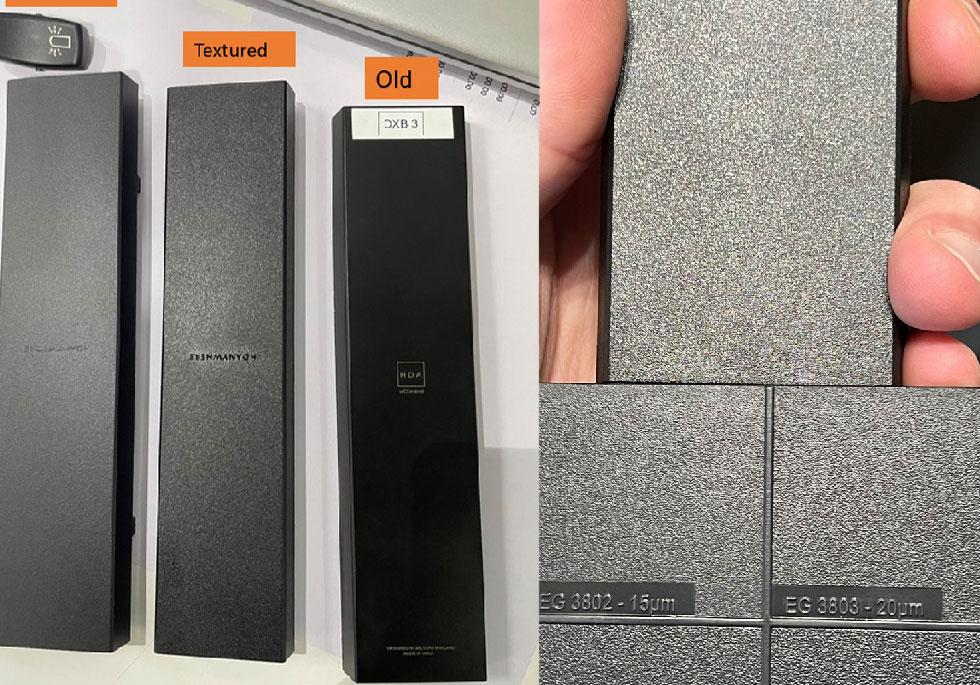

If you have been following the uControl Remote's journey so far, you will know that we were not 100% happy with the finish achieved with the plastic parts (casing, buttons and screen) from our first forays in to injection moulding.

But two steps forward and one step back is still progress. And with each "failure", the consequential design changes incrementally improve the overall quality, fit, finish and function of the final product.

We find solace in Elon's quote, "specialise in making the impossible merely late.” Even though we encounter setbacks, we remain committed to delivering the ambitious uControl Remote project soon!

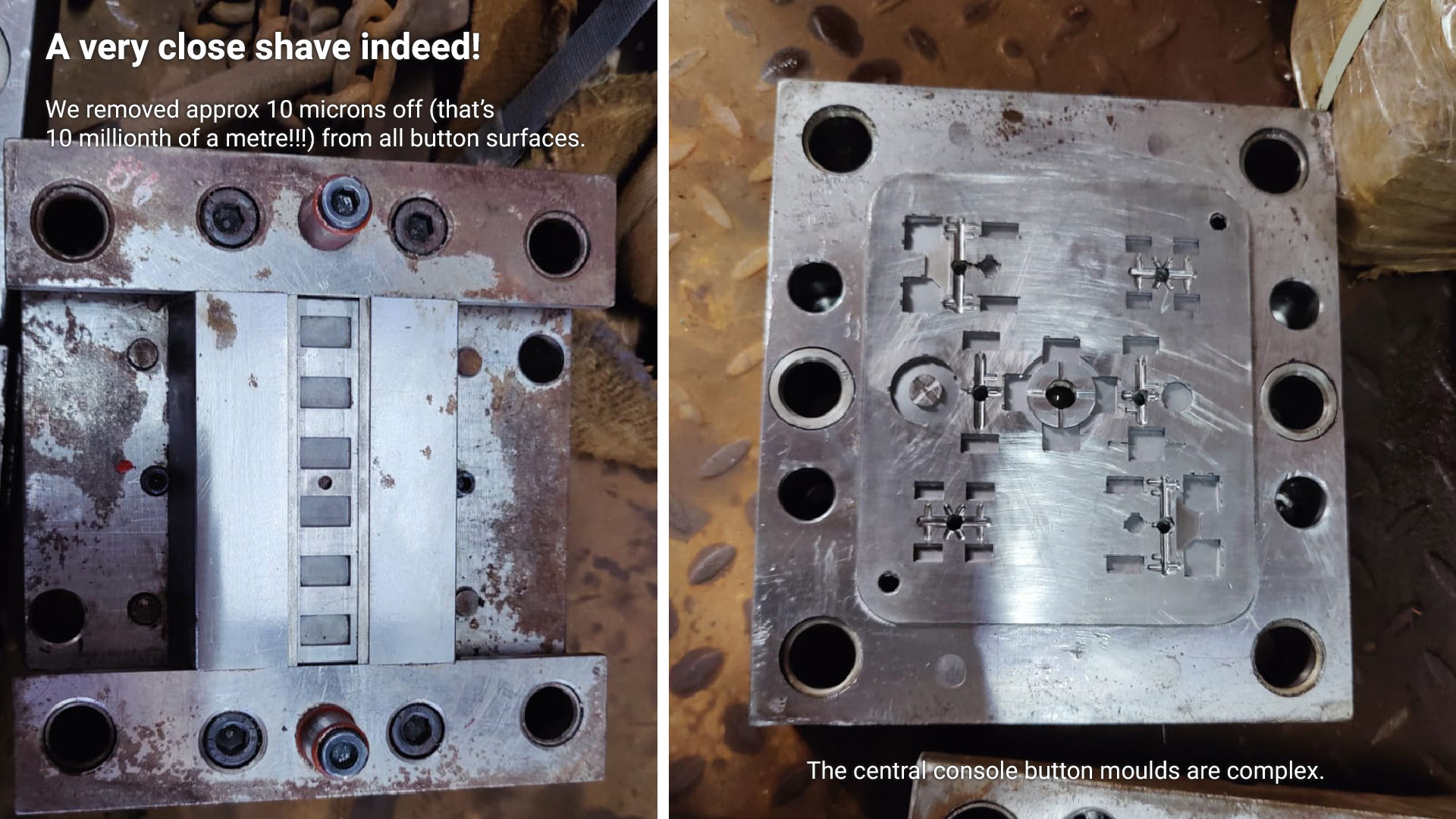

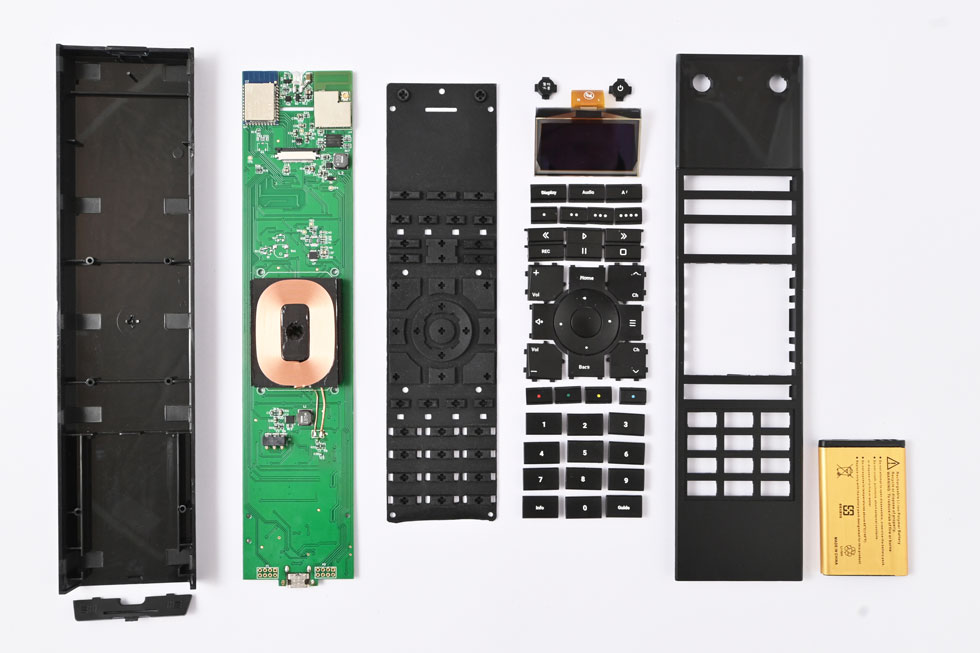

We have learned an enormous amount from this prototyping phase, which has lasted nearly a year. We now move to the product’s final design-for-manufacture (DFM) phase, where we have made several changes to the parts and components, and how the remote is assembled.

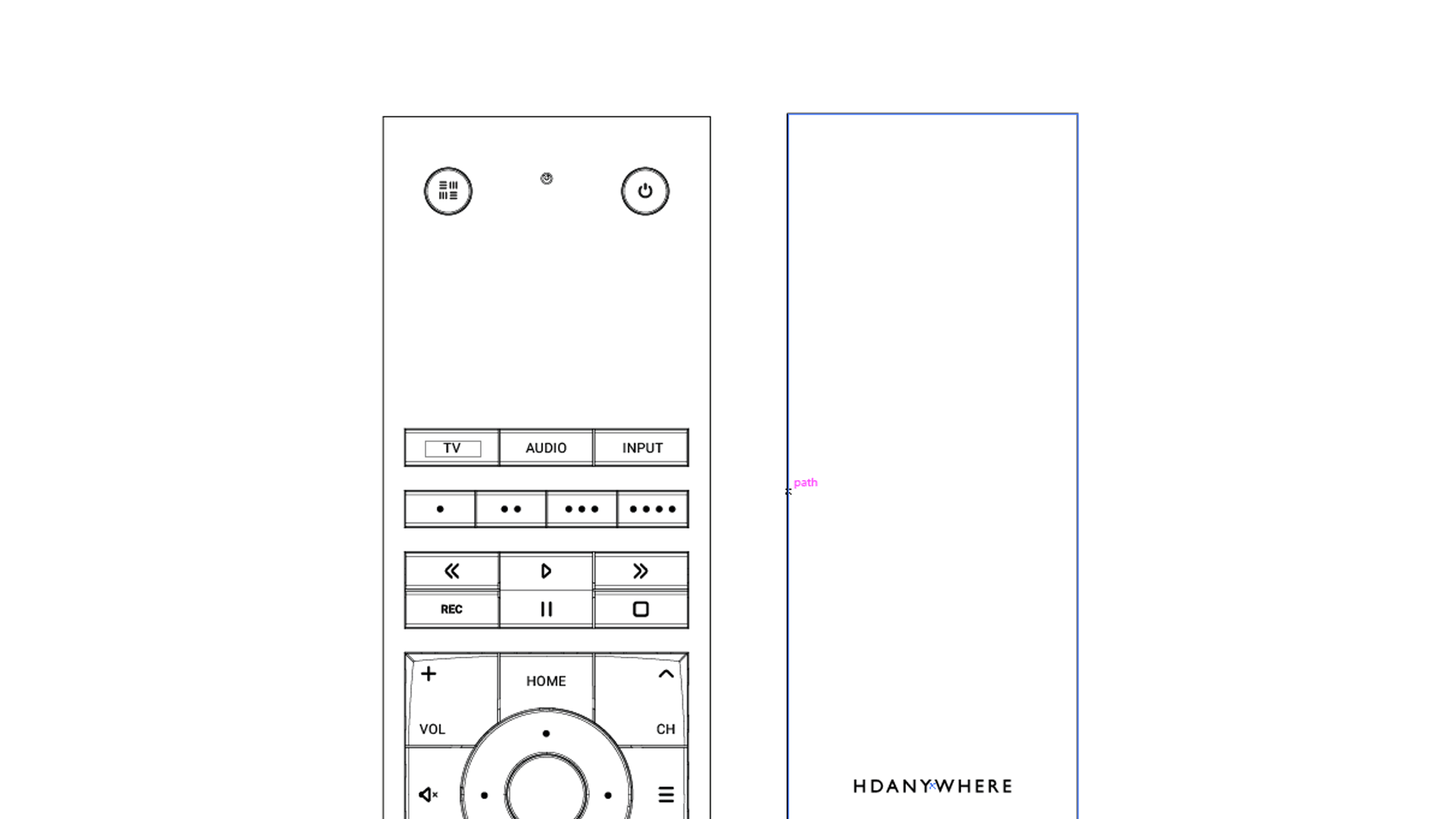

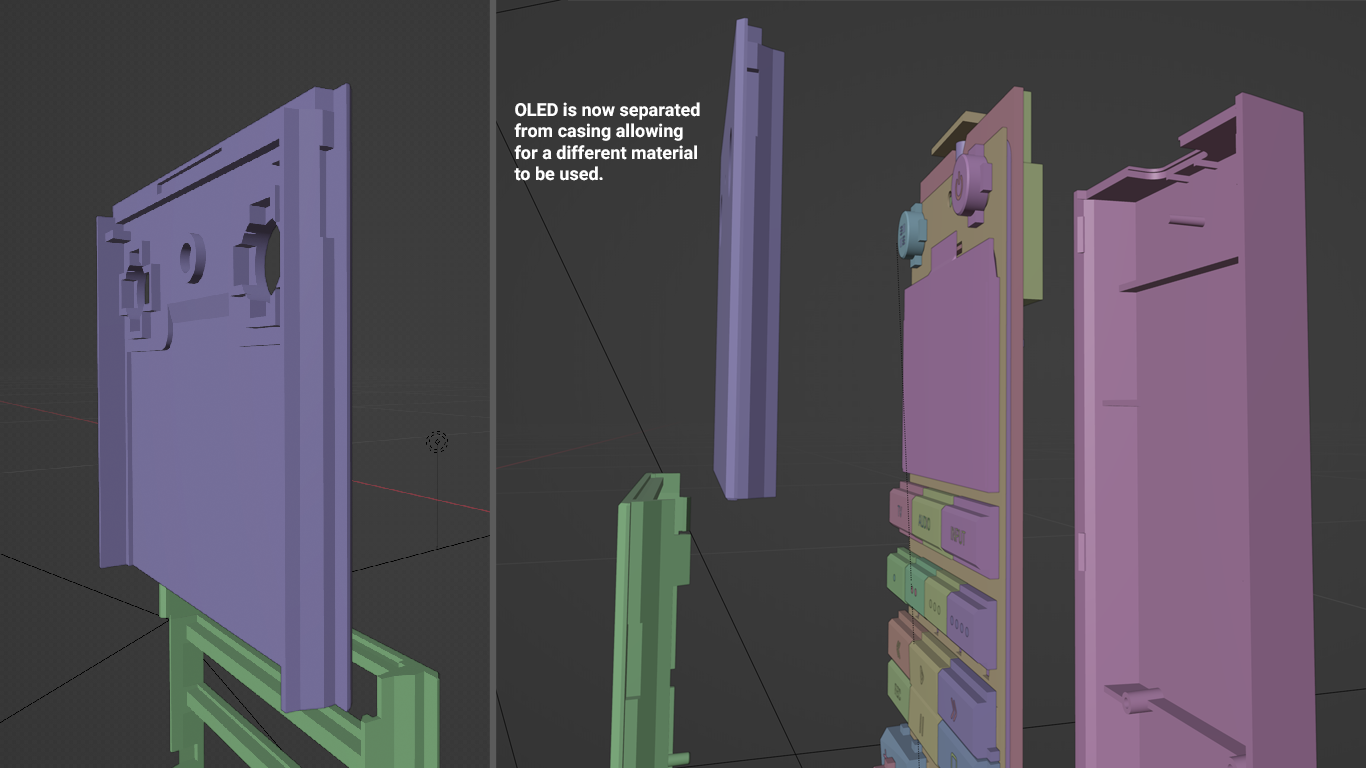

I’ve picked out a few things here in the CAD to show you the evolution of parts.

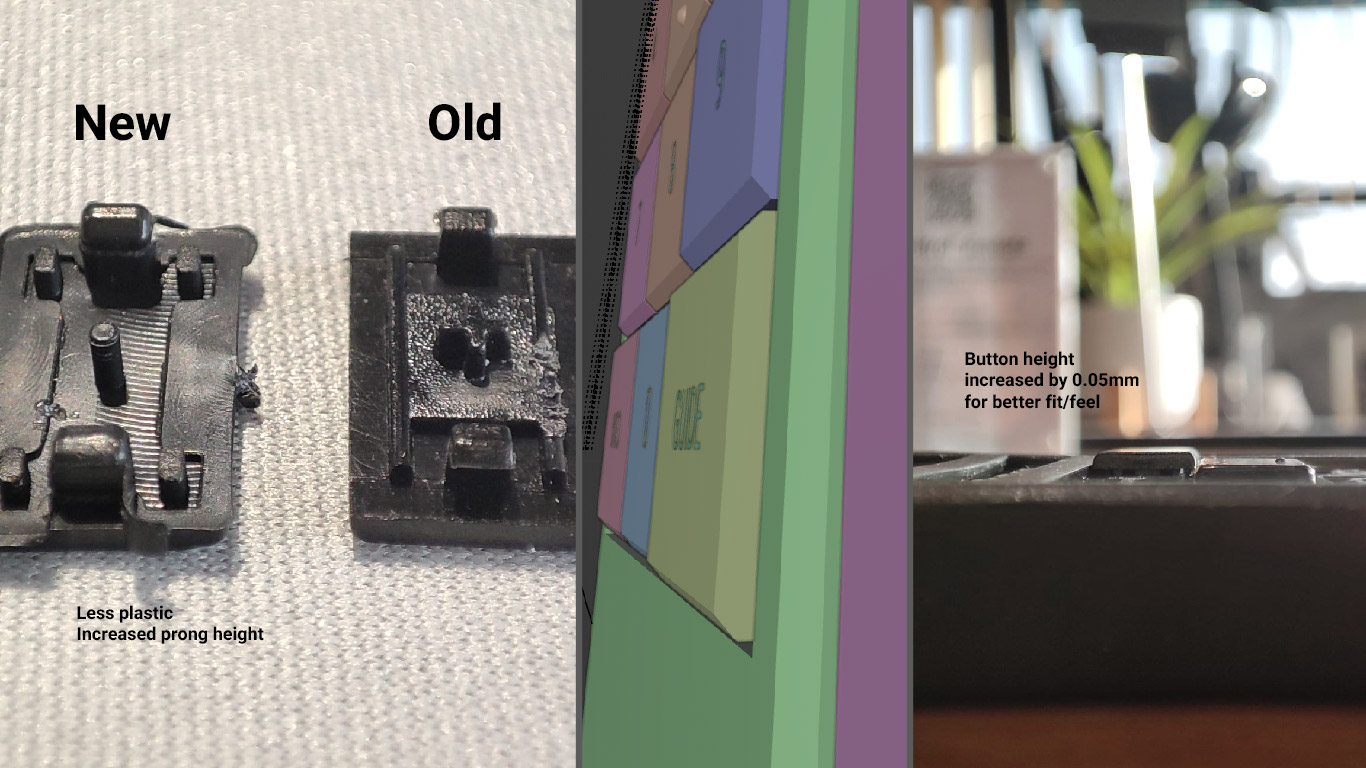

- Increase button height

- Create a single piece screen and IR window

- Improvements to battery housing

The OLED screen is no longer part of the front face and has been separated.

The buttons have been redesigned reducing the amount of plastic injected into the mould and the height has been increased.

To further expand my knowledge of the technology, techniques, and innovation happening in the UK’s plastics industry, I attended the leading plastics exhibition and conference, ‘Interplas’, in September at the NEC. By the end of the day, I was enthused about several new approaches we could take with the remote’s manufacture and with the bonus of doing it all in the UK. I came away from the show with new and improved ideas to implement, including laser powder bed fusion (LPBF) metal additive manufacturing for essentially 3D printed mould tools, glass-like polycarbonate with laser plastic welding for the screen, sustainable polymers for the case, and LED UV printing for the button text, to name but a few!

A new manufacturing partner located close to our Malvern HQ!

Today, I am pleased to write this blog update from an advanced manufacturing facility we're using to produce parts of the uControl Remote, which is only a short drive from our Malvern HQ! Although it was frustrating to start over and push back delivery timescales, ultimately, I know we made the right choice.

When will we be shipping?

Honestly, we are now closer than ever to being able to ship the first batches of remotes. I would urge you to register your interest to ensure you’re the first to know!

Do you have a question about the uControl Remote? Ask it in our uControl Development Tips and Tricks group.

Would you like to become a beta tester and help us make the uControl Remote as good as possible?

We’re looking for helpful HDANYWHERE installers with an MHUB in their showroom or home to give feedback on the uControl Remote setup, configuration, operation and performance. If you’re interested, let us know here.